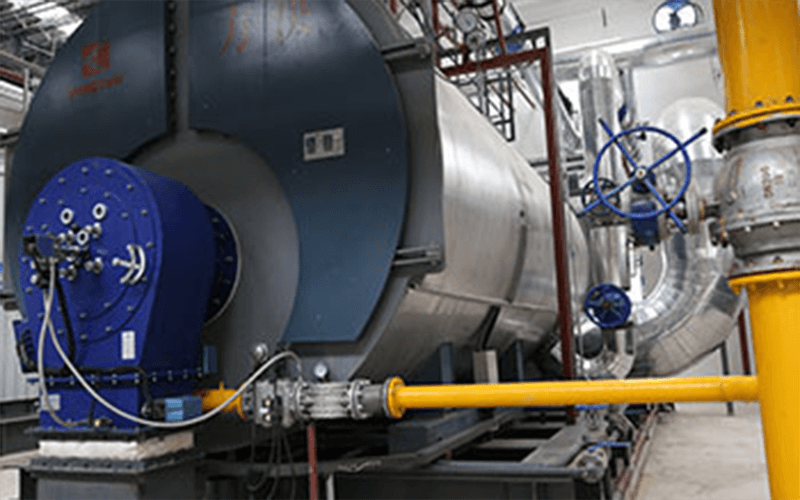

Gas-fired heating boiler using natural gas

Gas-fired heating boiler using natural gas

Gas-fired heating boiler using natural gas

A gas-fired boiler is heated with natural gas. The effective calorific value is only its low calorific value, about 8500 calories / cubic, and its high calorific value can reach more than 10000 calories. Therefore, the exhaust gas temperature can reach 220 degrees or so, a tube waste heat recovery device can be installed at the flue gas outlet, and the gas can be saved by more than 5% by using the flue gas heat heating preparation pump to feed the water into the gas heating boiler. According to the low calorific value, the thermal efficiency of gas heating boiler can be increased from 88% - 92% to 98%-102%.

1. The purpose of improving the condition of air flow meeting is to increase their contact area, and to improve the connection condition between gas and air flow in gas heating boiler. The larger the contact area, the larger the reaction area, which strengthens the combustion. Specifically, the gas and air can be divided into multiple streams of fine streams, so that the two streams of air have a certain speed and cross-encounter; one air flow (usually gas) passes through and inundates in another stream, and so on.

2. The combustion of gas fuel in perturbed gas heating boiler is a single-phase reaction, and ignition and combustion are easier than solid fuel, but its combustion rate and combustion perfection are closely related to the mixing of gas and air. The better the mixture, the faster it burns, the more complete it is, and the shorter the flame. Therefore, as long as the stability of the flame is not destroyed, the velocity of the air flow in the air outlet or combustion chamber should be increased as far as possible, and even the baffle should be set up at the entrance so that it can press, flushing and increase the disturbance of the air flow in order to strengthen the mixing.

3. Preheating gas and air can enhance combustion reaction by increasing the temperature of gas and air. Therefore, the residual heat of smoke exhaust should be used to preheat the gas and air temperature, so as to improve the combustion temperature and flame propagation speed, so that the combustion process can be strengthened.

4. Rotating and circulating airflow promote airflow rotation to enhance disturbance and mixing. At the same time, a large number of flue gas reflux will be guided in the center of the rotating air flow, which not only strengthens the mixing, but also prolongs the flow route and stay time of the flue gas in the gas heating boiler, and reduces the incomplete combustion loss.

5. In order to increase the temperature of combustion reaction zone of gas heating boiler, part of high temperature flue gas can be directed to combustion, so that it can be mixed with the final combustion or combustible mixture in order to improve the combustion intensity. However, it should be noted that the amount of recycled smoke should not be too large, otherwise it will dilute the combustible mixed hook because of too many lazy substances, instead, the combustion rate will be slowed down, even anoxic pyrolysis, resulting in incomplete combustion loss of gas heating boiler.