Principle of "called Water" in Gas heating Boiler

Principle of "called Water" in Gas heating Boiler

Principle of "called Water" in Gas heating Boiler

Principle:

When the water release cock is turned on, and then the cock between the steam, water connecting pipe and the water level meter is closed, the water level meter is connected with the big steam, and the pressure in the water level meter is zero. At this time, close the discharge cock and open the water cock between the water connecting pipe and the water level meter, because the pressure in the pot tube is higher than the pressure in the water level meter, if the water level of the drum is near the water connecting pipe, the water will be brought into the water level meter by the steam flow. This shows that the degree of water shortage is not serious. If there is always no water level in the water table after "called water",

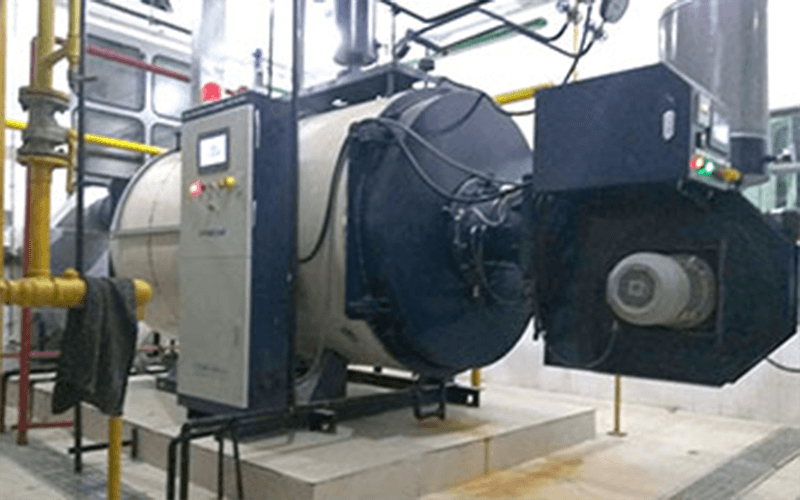

When the water level of gas heating boiler can not be seen, the method of flushing water level meter is used to judge whether the water is short of water or full of water. If the water level meter is judged to be short of water, the gas heating boiler whose water connection pipe is lower than the highest fire boundary should immediately stop the furnace urgently, reduce the furnace temperature and close the main steam valve and the water supply valve. For gas heating boilers with large water capacity and higher water connecting pipe than the highest fire boundary of gas heating boilers, the severity of water shortage can be judged by the method of "called water", so as to take corresponding measures.

When the water shortage is not serious, the gas heating boiler can continue to feed water, and after the normal water level is restored, the combustion equipment can be started to heat up gradually and the pressure can be put into operation.

Through "called water", when it is judged to be seriously short of water, the furnace must be shut down urgently and blindly feed water to gas-fired heating boiler. Fluke psychology must not be allowed to blindly feed water in an attempt to cover up the responsibility of causing water shortage in gas-fired heating boilers. This kind of mistake often leads to great disaster, expands the accident, and even causes the gas heating boiler to explode and destroy the furnace to death. It is considered that the shortage of water is more serious.

261what kind of soot blower is good for gas heating boiler?

In terms of safety, it is acoustic soot (acoustic soot blowing is the wrong term!) Best; in terms of performance-to-price ratio, it is also acoustic soot cleaning;

Steam soot blower is jet soot blowing, far away can not blow, near will blow the equipment;

Shock wave soot blower (should be called pressure wave soot blower), deflagration produces shock wave (also known as shock wave), pulse sound wave and pulse flow, in which shock wave, energy is limited and has certain directivity, pulse acoustic wave action time is too short. Pulse air flow and steam jet have the same advantages and disadvantages. When the nozzle is facing the heat exchanger, the pulse air flow is the main ash blowing, the ash blowing effect is good, but it has damage to the heat exchanger; when the nozzle is not facing the heat exchanger, the shock wave is the main ash cleaning, the effect is not good; the operation cost is too high!

Sound wave ash removal is good, that is to say, the sound wave used for ash removal can be done: enough energy, appropriate frequency and correct operation program! Otherwise, it is not necessarily what; that is to say, if you choose sound wave ash cleaning, you must choose sound wave generator with large acoustic energy, but also depends on whether the manufacturer has a certain level of acoustic ash cleaning technology, which is very important!